Triumph Originals: one bike, one team, one dream

Eight countries. Eight teams. A single ambition: to reinvent the Triumph Bonneville through a unique preparation, combining British tradition and contemporary vision. The Triumph Originals 2025 competition highlights the best customization workshops from around the world. Each team proudly represents its country and works hand in hand with Triumph Motorcycles to deliver its own interpretation of the “Icons of British Originality”.

In France, it’s our workshop: FCR Original, which has been selected to carry the colors of French mechanical elegance. It’s an immense honor, and a major challenge: to design an exceptional motorcycle, faithful to our DNA, while respecting the historic values of the British brand.

Today, after months of intense creative work, we are proud to unveil the fruit of this collective labor.

A project that embodies the FCR Original spirit

For FCR Original, participating in Triumph Originals isn’t just a competition. It’s an opportunity to represent what we are: a close-knit, passionate team, where every project is driven by attention to detail, performance and mechanical beauty. This global challenge has shaken up our daily lives, awakening in us a healthy competitive spirit, fuelled by the desire to surpass ourselves.

This project symbolizes the encounter between the vision of an independent company and the influence of an iconic brand like Triumph.

It was also an opportunity to fully assume our identity as creators: that of a craft workshop where each motorcycle is conceived as a rolling work of art. And because we never win alone, this project has been experienced as a human adventure, rich in sharing, debate and new ideas.

Passionate teamwork

This bike is the work of a passionate and committed team. Each of them has put his or her expertise at the service of a common goal: to create a radical, elegant and high-performance Triumph.

Sébastien

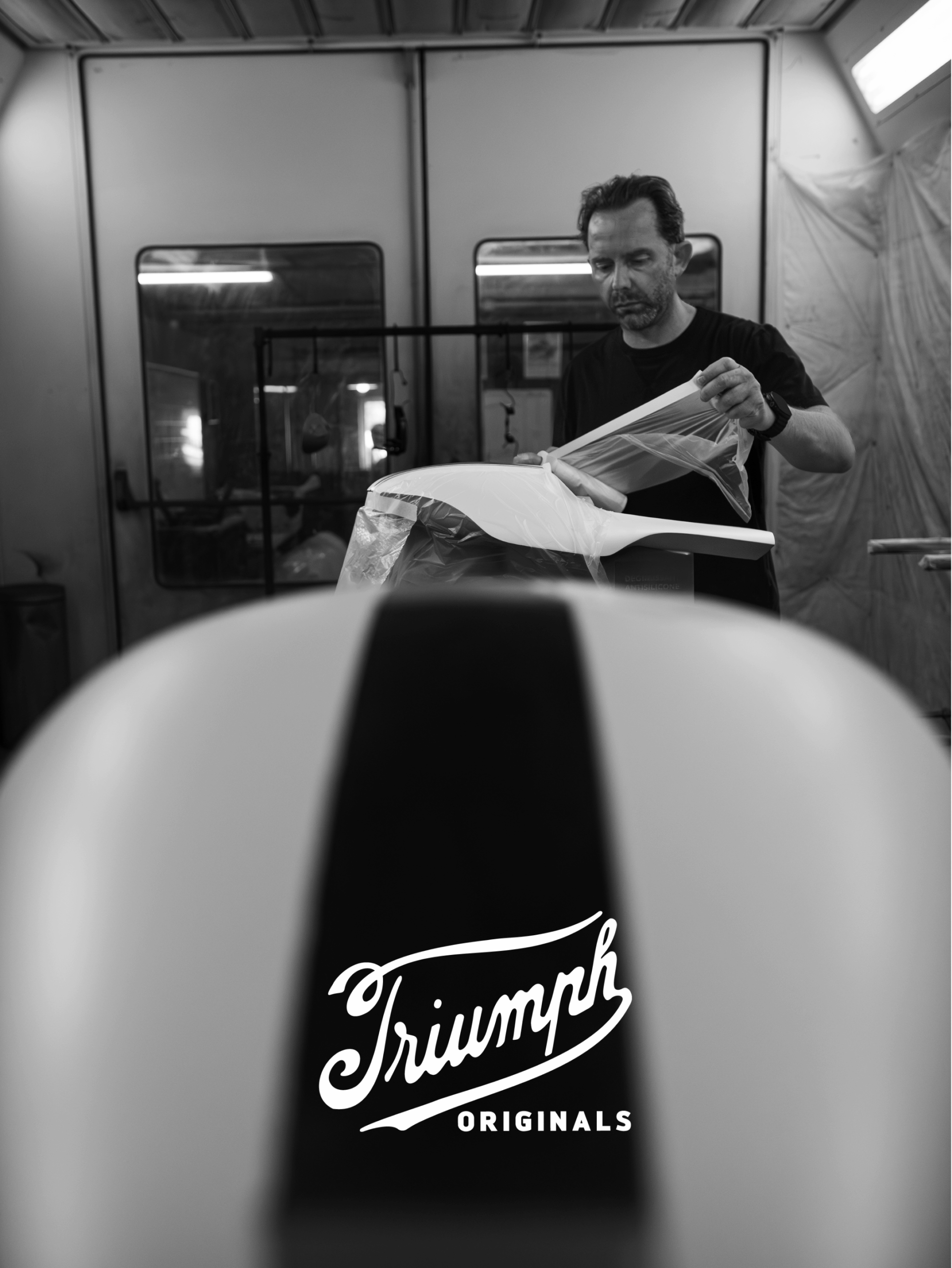

Founder of FCR Original, he passionately oversaw the entire project. He brought his vision to bear on the bike’s overall lines, finishes and aesthetic direction. As an expert in custom motorcycling, he also lent his hand to certain key stages, notably the paintwork. His in-depth knowledge of mechanics and aesthetics enabled him to guide the team with coherence.

Benjamin

A metal expert, he reconfigured the machine’s skeleton. He designed the bespoke swingarm, welded the structural elements, produced the dry pipe exhaust system and assembled the sub-assemblies. A complete transformation in which each weld becomes a signature. Every

Yoann

A true mechanical wizard, he single-handedly handled all mechanical operations on the bike, from complete disassembly to final assembly. His great expertise and detailed understanding of each component enabled him to adapt, adjust and integrate complex solutions with rigor and inventiveness. His technical eye and attention to detail make him a cornerstone of this preparation.

Céline

A painter and finishing specialist, she sublimated each element with patience and exacting standards. She prepared the 3D-printed rear hull, produced its fiber version, sanded, primed, painted, applied gold and copper leaf by hand, and varnished every part, from flanges to engine casings. A visual signature of great finesse, blending modernity, craftsmanship and refinement.

Alex

As a designer in the engineering department, he was the conductor of the bike’s visual and functional creation. He drew up the first lines of the project, designed the machined rims, imagined the custom CNC parts and the technical interfaces. He took innovation a step further by modeling specific parts in 3D. Throughout the project, he ensured aesthetic consistency and technical precision.

Benoît

An essential link in the production chain, he orchestrated all the logistics with impressive rigor. He took delivery of the Speed Twin, prepared the project in advance, placed orders, managed suppliers and anticipated every stage of assembly. He ensured continuous supply, sandblasting and outside operations. Thanks to his constant involvement, the project maintained its pace and efficiency.

Arthur

As a content creator and photographer, he captured every key stage of preparation. He documented the workshop’s daily routine, technical moments and team exchanges. He handled all the shootings, photo retouching and visual content posted. His expertise, aesthetic sensitivity and understanding of the project conveyed the intensity of the adventure.

Max

An expert in digital communications, he steered the project’s launch strategy. He coordinated publication schedules, wrote texts, put web content online and structured all distribution channels. Thanks to his global vision, he gave the project a strong editorial coherence, capable of reaching both enthusiasts and neophytes.

Mathéo

As an apprentice in the engineering & design department, Mathéo played a fundamental role in the preparatory phase of the project. He was the first to 3D scan the Triumph Speed Twin RS, creating a complete digital model of the bike. He conducted in-depth research into suspension kinematics and laid the technical foundations for the project.

To symbolize this spirit of family and craftsmanship, each member of the team has signed the rear hull, like a team manifesto. A strong, sincere gesture that marks this bike as

A technical and aesthetic creation by FCR Original

Behind its radical, uncluttered appearance, this Speed Twin 1200 RS hides a thorough workout on every level: aesthetic, technical and functional. Every part of the workshop has contributed to making this motorcycle an exceptional piece, where innovation meets craftsmanship.

The structure has been redesigned from A to Z: bespoke swingarm, removal of the rear loop, complete transformation of the suspension system with the installation of a central monoshock. The new geometry lowers the center of gravity, refines the lines and enhances the machine’s sportiness.

The engine block has been lightened visually and mechanically: airbox removed, direct intake, acid-etched crankcases, dry-pipe exhaust system for a raw, unfiltered sound. The bike breathes freely, and its mechanical heart is proudly exposed.

At the front, the custom-machined rim, carbon fender, polished quills, streamlined controls and compact headlamp give the front end a sharp, futuristic silhouette. The one-piece CNC speedometer holder, designed in our engineering department, completes the minimalist cockpit.

As for theoverall aesthetic, it draws on the history of British design while breaking codes: carbon rear flanges, pearly white and racing red paintwork, gold leaf and copper details, all punctuated by “Hail to the Twin” lettering in a nod to Triumph’s legendary engine. Every detail, from the engine block to the rims, reflects the balance between performance, nostalgia and modernity.

This motorcycle is a concentration of our know-how: machining, welding, painting, design, prototyping, composition, all guided by a common requirement. A project conceived, built and finalized hand in hand, right down to the collective signature on the tank: the symbol of a deeply human and resolutely FCR Original project.

Voting is open: we need your help

Today, we need your help.

Voting means recognizing the work of an entire team of enthusiasts who have put their hearts, ideas and sweat into creating a different, sincere and ambitious motorcycle. It also means encouraging an independent vision of motorcycle preparation. An artisanal, human and collective preparation.

Visit the Triumph Originals website to discover the competing creations and vote for France and FCR Original.

Every vote counts.

Thank you for all your support over the years, and we’re on our way to first place.

Photo & video credits: FCR Original